The mirror does not get pulled from the 60-inch telescope until Monday, but the process of getting ready for the job began quite a while ago. I thought I would show one piece of that process that I have not documented before. One of the key elements in re-coating a telescope mirror is the preparation of the filaments that go into the aluminizing chamber.

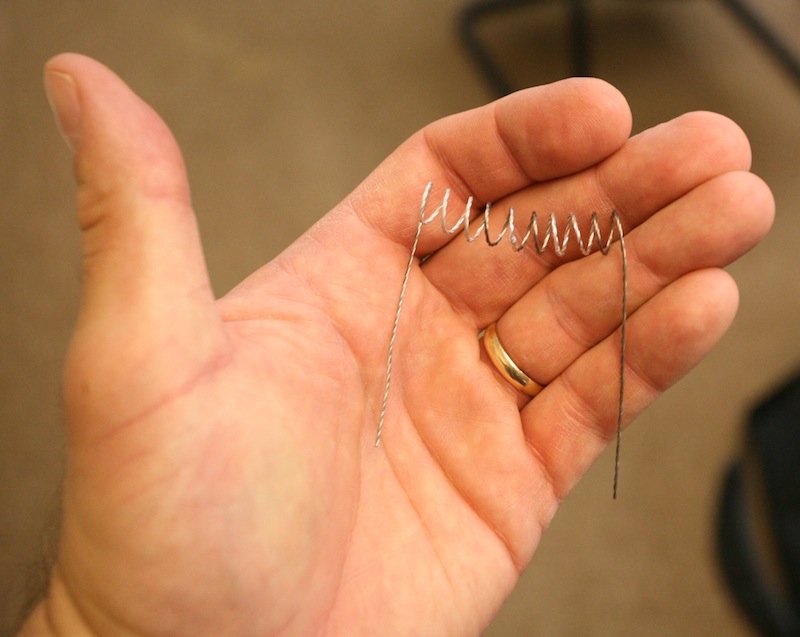

The big task is to melt some of these:

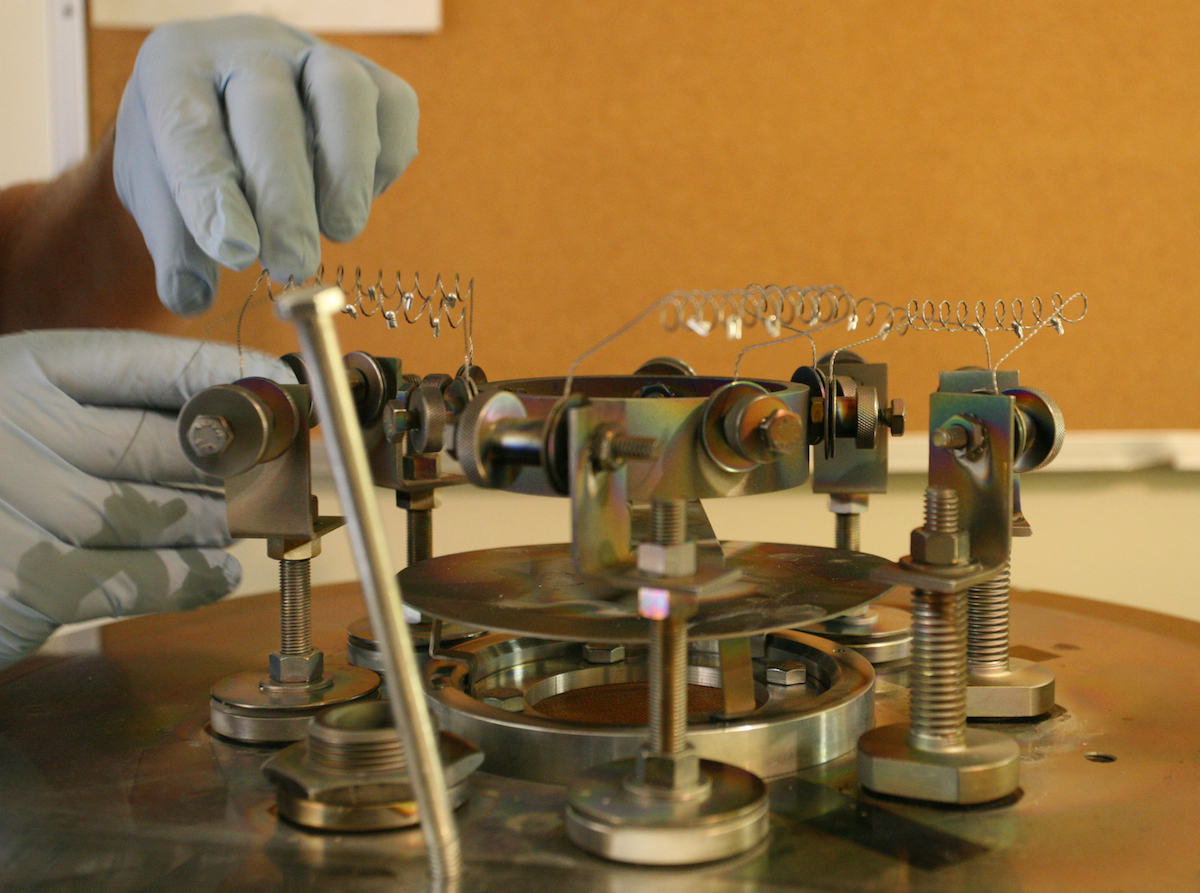

onto thirty two of these:

onto thirty two of these: Specifically 0.165 grams of aluminum (about 3 of the pieces shown above) gets melted on each of the 32 tungsten wire coils. Those coils get placed into the aluminumizing chamber where a total of 5.28 grams of aluminum gets vaporized to provide a thin, even coating of the top surface of the mirror.

Specifically 0.165 grams of aluminum (about 3 of the pieces shown above) gets melted on each of the 32 tungsten wire coils. Those coils get placed into the aluminumizing chamber where a total of 5.28 grams of aluminum gets vaporized to provide a thin, even coating of the top surface of the mirror.To get the wire coils prepared the aluminum pieces are draped on the coils which are then attached to this device which holds just 6 coils:

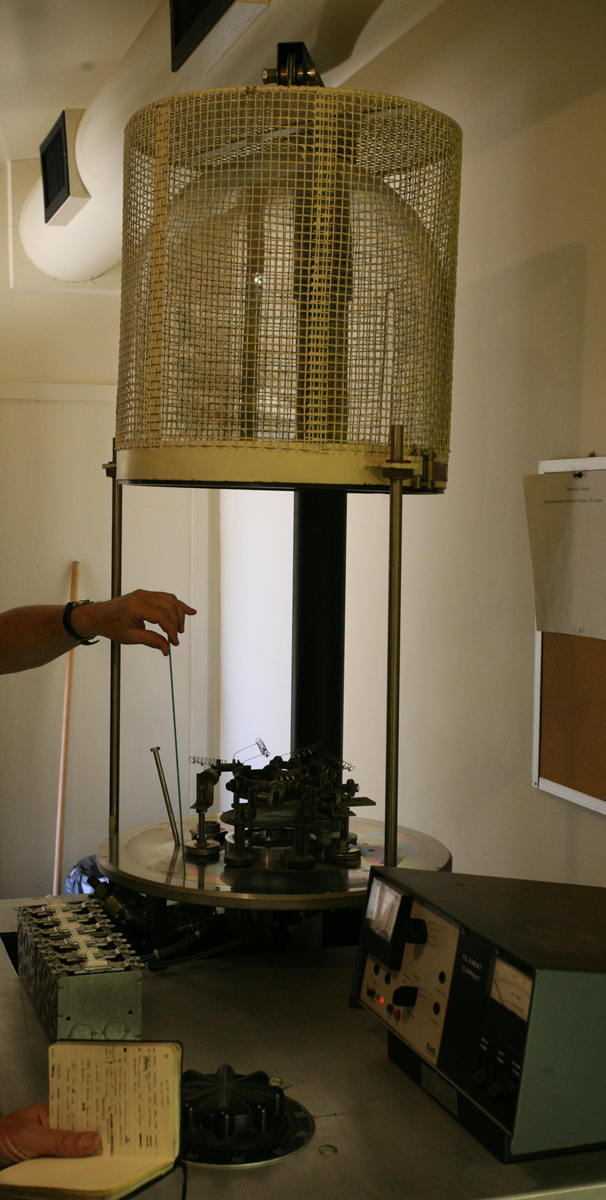

A glass bell jar with a protective wire cage is lowered over the device and the bell jar is pumped down to a vacuum.

Once a vacuum has been achieved electric current is individually applied to each of the coils in turn.

This is actually done twice. Once to melt the three staple-like pieces of aluminum to the coil. The second application actually causes the melted aluminum to wick out across the wire filament which will later help to provide a more even coating to the glass surface.

The prepared coils are later loaded into the aluminumizing chamber. Next week, once the 60-inch mirror is washed, stripped, and fully clean and dry it will join them as the new coating is applied.

No comments:

Post a Comment