If you look carefully just to the upper left of the mirror you can see that there was something taped to the ring that surrounds the glass. That is one of the four "witness slides" that were placed inside the tank. Since everything on the inside of the chamber gets a coating of aluminum the slides can be used to study the aluminum that was deposited.

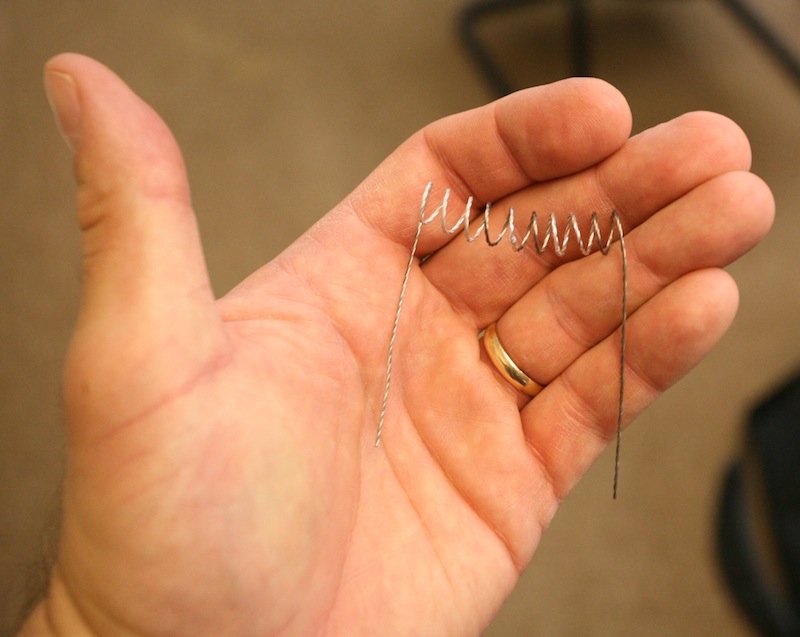

Here is a closeup of one of the witness slides where it was aluminized:

And one, with the tape removed:

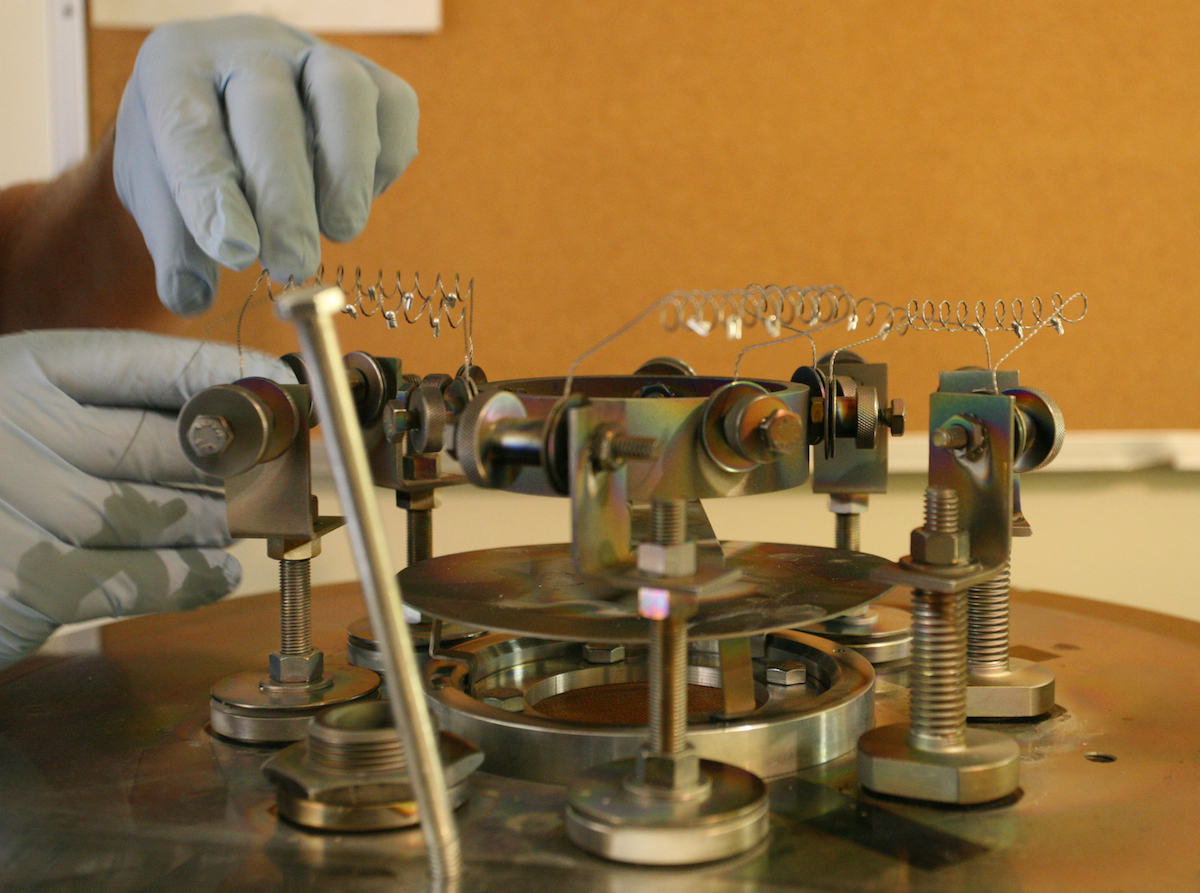

With the sample and the tape removed it is possible to measure the thickness of the aluminum coating, which is useful to know to try and improve the process for future coatings.

The tape that held the witness slides in place was clear. Like the slides, the mirror and everything inside, the tape was also coated with a thin layer of aluminum.

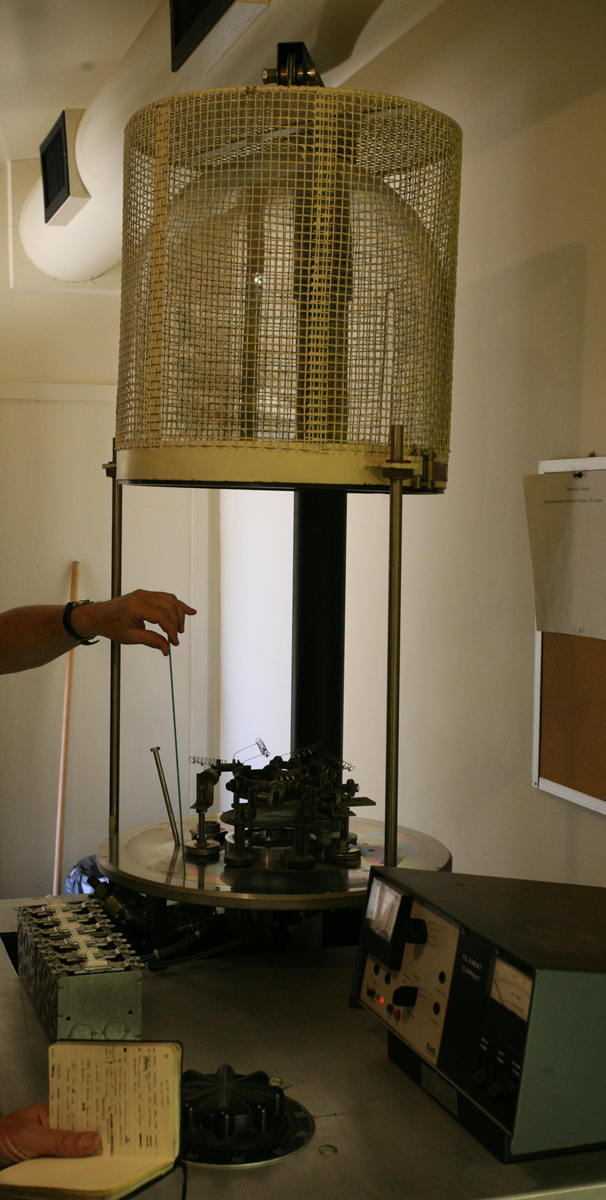

If everything on the inside of the chamber was coated with aluminum, why isn't everything nice and shiny? It is only the materials that are very smooth, like glass, that give a good reflective coating.

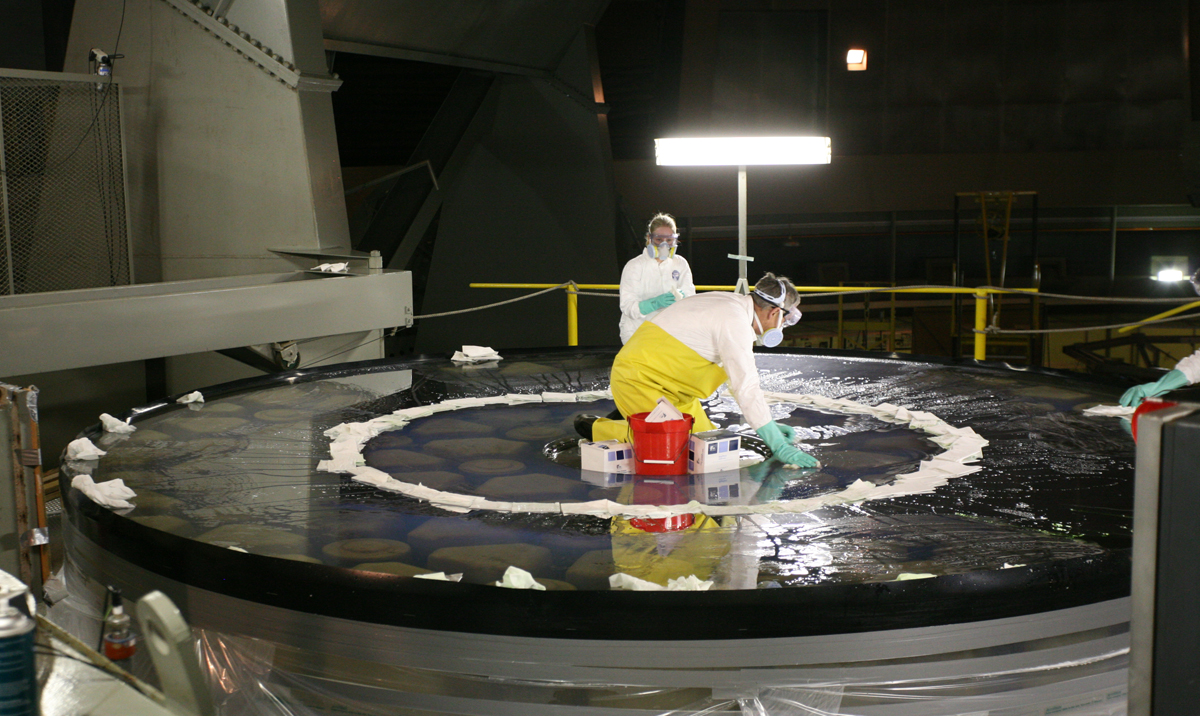

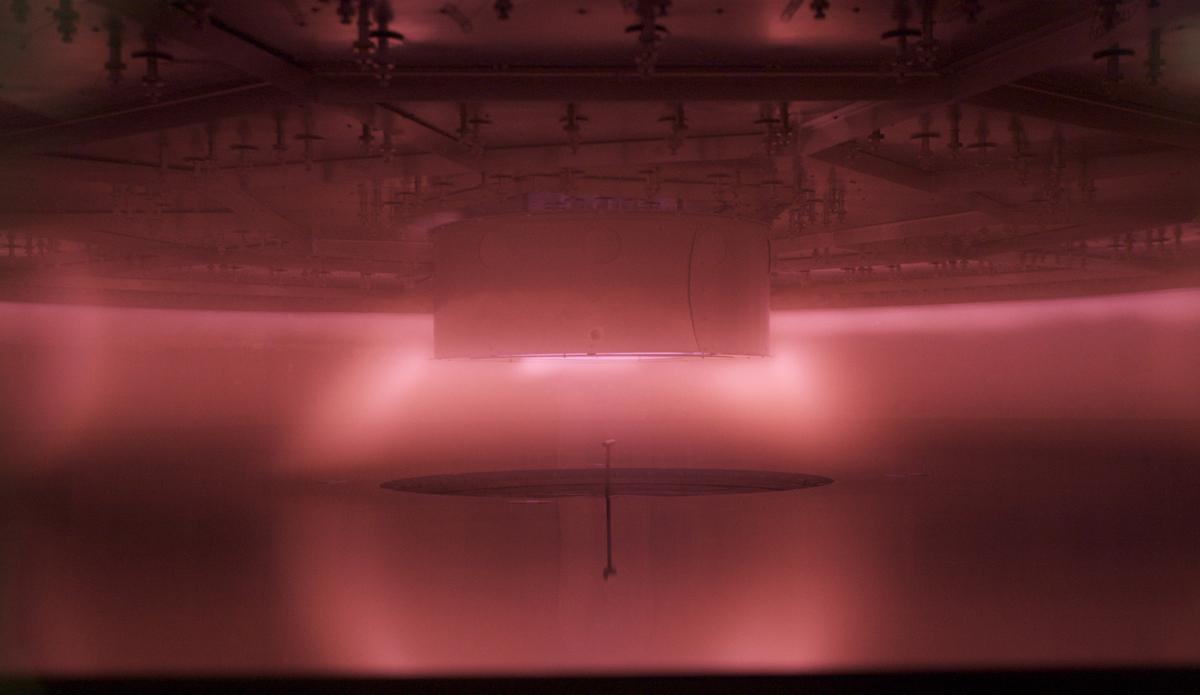

Finally, to close out my coverage of re-coating the 60-inch mirror, here it is as it was being returned to the telescope: